There are not many chemistry labs that begin their experiments by first baking fresh bread. Yet, that is exactly what a lab headed by Yibin Li at the Harbin Institute of Technology in China does in its pursuit of cheap and effective carbon foam.

As its name suggests, carbon foam is a porous, light-weight material made mostly of carbon. Because it has low thermal conductivity (i.e., it does not transfer heat very well) and is largely fire resistant, it could be useful as an insulator in buildings.

Graphene, a layer of carbon that is a single-atom thick, could be used to make carbon foam, but manufacturing graphene is costly and complex. Other researchers have converted biomass, such as watermelons and banana peels, into carbon foam. This is cheap, but because there is no control over the size and shape of the pores that form, the quality suffers.

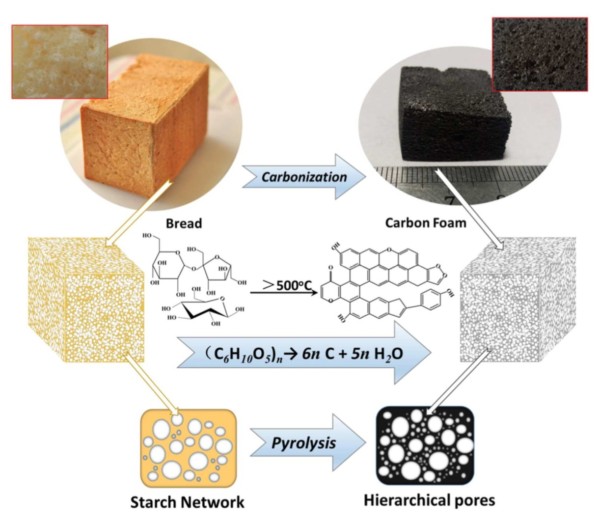

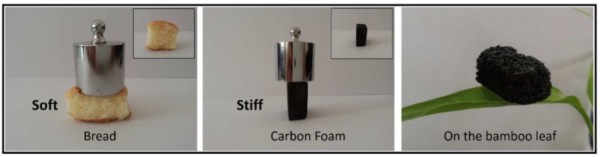

One day at breakfast, Dr. Li realized that bread -- with its fluffy, porous texture -- had just the structure for producing ideal carbon foam. So, the lab baked bread and subjected it to pyrolysis, a chemical reaction that converts organic compounds into mostly carbon by heating them in the absence of oxygen. (See figure.)

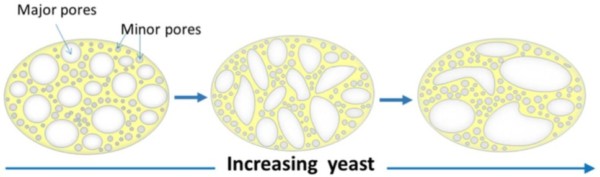

Additionally, the researchers were able to control the size of the pores by tinkering with the amount of yeast and water they used to bake the bread. Larger and more disordered pore structures could be created by adding either more yeast or water.

Larger pores in carbon foam made from bread can be created by more yeast or water. (Ye Yuan et al., ACS Appl. Mater. Interfaces, 2016.)

Larger pores in carbon foam made from bread can be created by more yeast or water. (Ye Yuan et al., ACS Appl. Mater. Interfaces, 2016.)

The resulting carbon foam was stiff, strong, and light-weight.

Further tests demonstrated that their bread-derived carbon foam had low thermal conductivity as well as an ability to shield electromagnetic fields. These features, combined with its being strong and light-weight, make the team's carbon foam potentially useful to aerospace engineers. The foam also retained its shape after being soaked in alcohol and burned, demonstrating its resistance to fire.

Perhaps the greatest advantage to using bread as a raw material is that you can eat whatever you don't use. That's rather uncommon in a chemistry lab.

###

Source: Ye Yuan, Yujie Ding, Chunhui Wang, Fan Xu, Zaishan Lin, Yuyang Qin, Ying Li, Minglong Yang, Xiaodong He, Qingyu Peng, and Yibin Li. "Multifunctional Stiff Carbon Foam Derived from Bread." ACS Appl. Mater. Interfaces 8 (26): 16852–16861. Published: June 13, 2016. DOI: 10.1021/acsami.6b03985